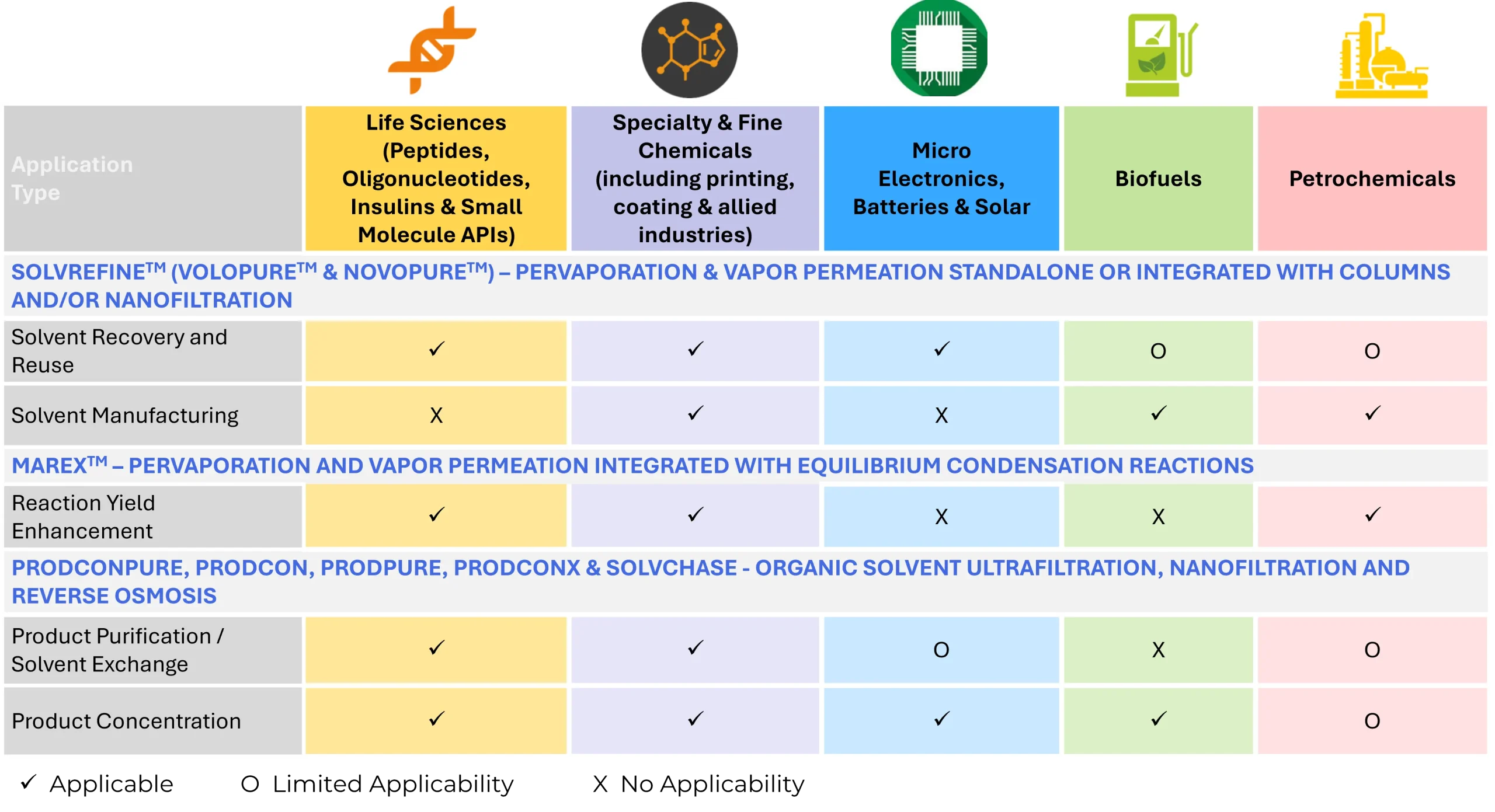

For Homogeneous Azeotrope & Pinched Organic Solvent-Water Mixture Separations in Manufacturing & Recovery

(Tetrahydrofuran, Isopropanol, Acetonitrile, Dimethylformamide, Ethanol, MEK, Acetone and Other Solvents)

For driving equilibrium condensation reactions forward to completion resulting in drastically lower reaction time and reduction in downstream separations

(Esters, Amidoamines and Other Specialty Chemicals)

For Non-Thermal Product Concentration & Solvent Purification

(Peptides, Oligonucleotides, Small Molecule API, Essential Oils, Specialty Chemicals, Photoresists etc.)

For Non-Thermal Product Purification & Solvent Exchange

(Peptides, Oligonucleotides, Small Molecule API)

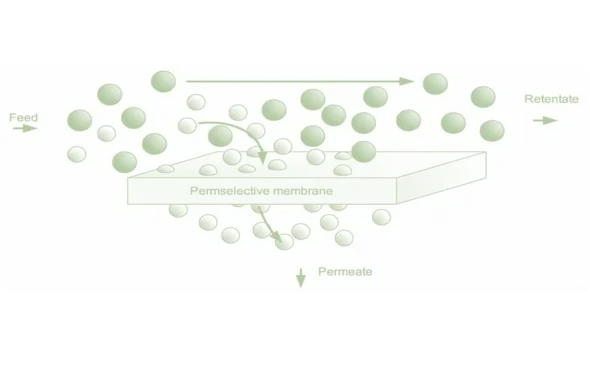

PERVAPORATION (PV) & VAPOR PERMEATION (VP)

Pervaporation (PV) and Vapor permeation (VP) are membrane separation techniques which are used to separate or recover components from liquid or vapor mixtures respectively by selective permeation.

Founded in 2003, I Cube Nanotec India LLP & i3 Nanotec LLC (collectively ICN) has served customers all around the globe and drastically reduced their carbon footprint.

CUSTOM DESIGNED & ENGINEERED SYSTEMS

ICN has 360 degrees Molecular Separations Expertise and has the capability to develop a novel process, process design, engineering and execute a modular system project in a wide range of industrial sectors.

GLIMPSE OF FEW EXECUTED PROJECTS

“The System is performing as per Guaranteed specifications and based on our 8 years plus experience so far, we are happy with this Innovative Nanotechnology-based Separations Process, as well as the back-up services that were rendered by I Cube Nanotec and have no hesitation in recommending this system to others.”

i3nanotec © 2024 All Rights Reserved.