VAPOR PERMEATION (VP)

Vapor permeation (VP) is a membrane separation technique which is used to separate or recover components from mixtures in vapor phase by selective permeation. Zeosep® Vapor Permeation technology using Zeolite membranes is effectively used for many applications like Solvent Drying, Solvent Recovery, etc.. as given in below table.

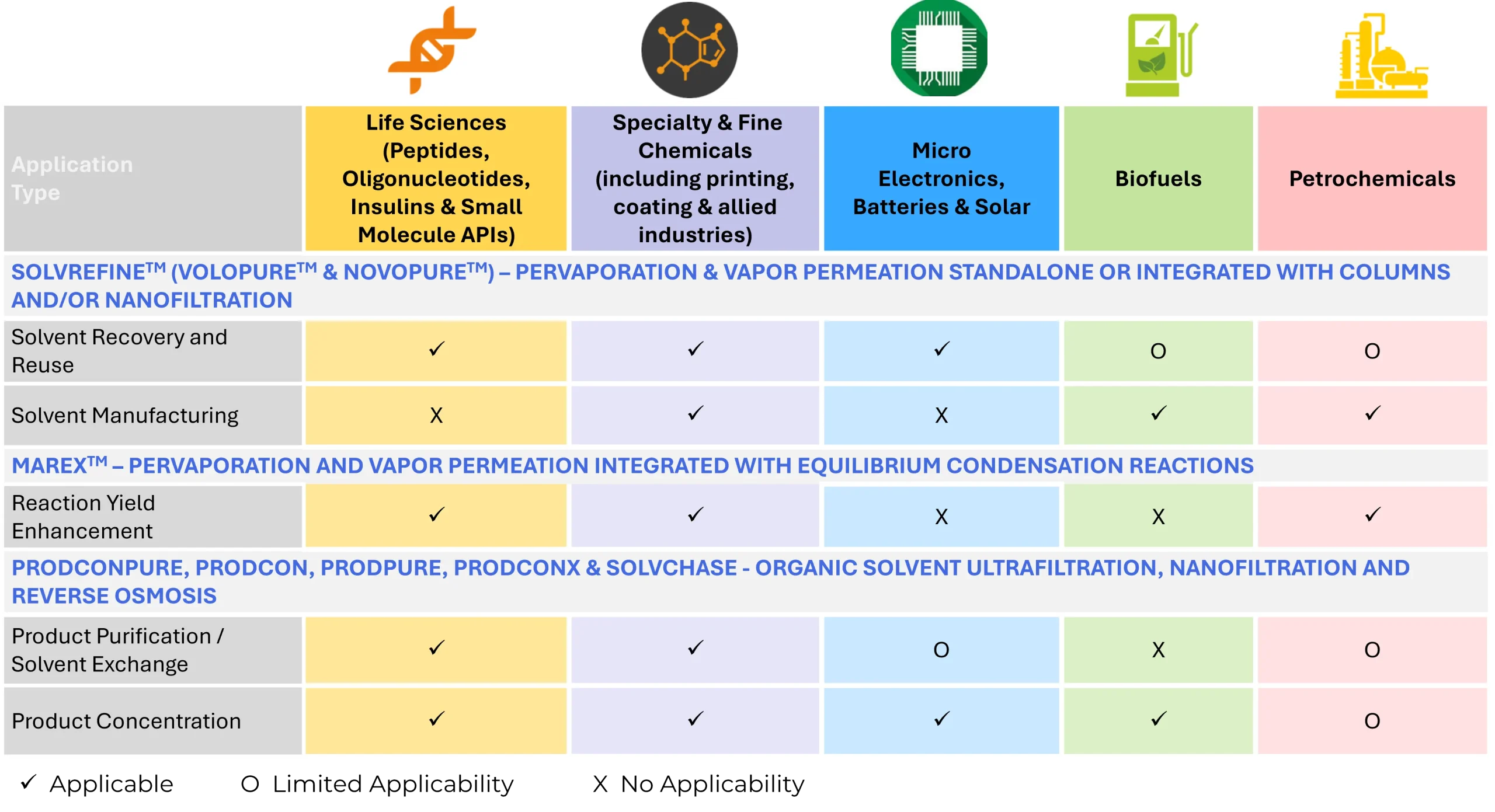

Applications in Our Focus Industrial Sectors

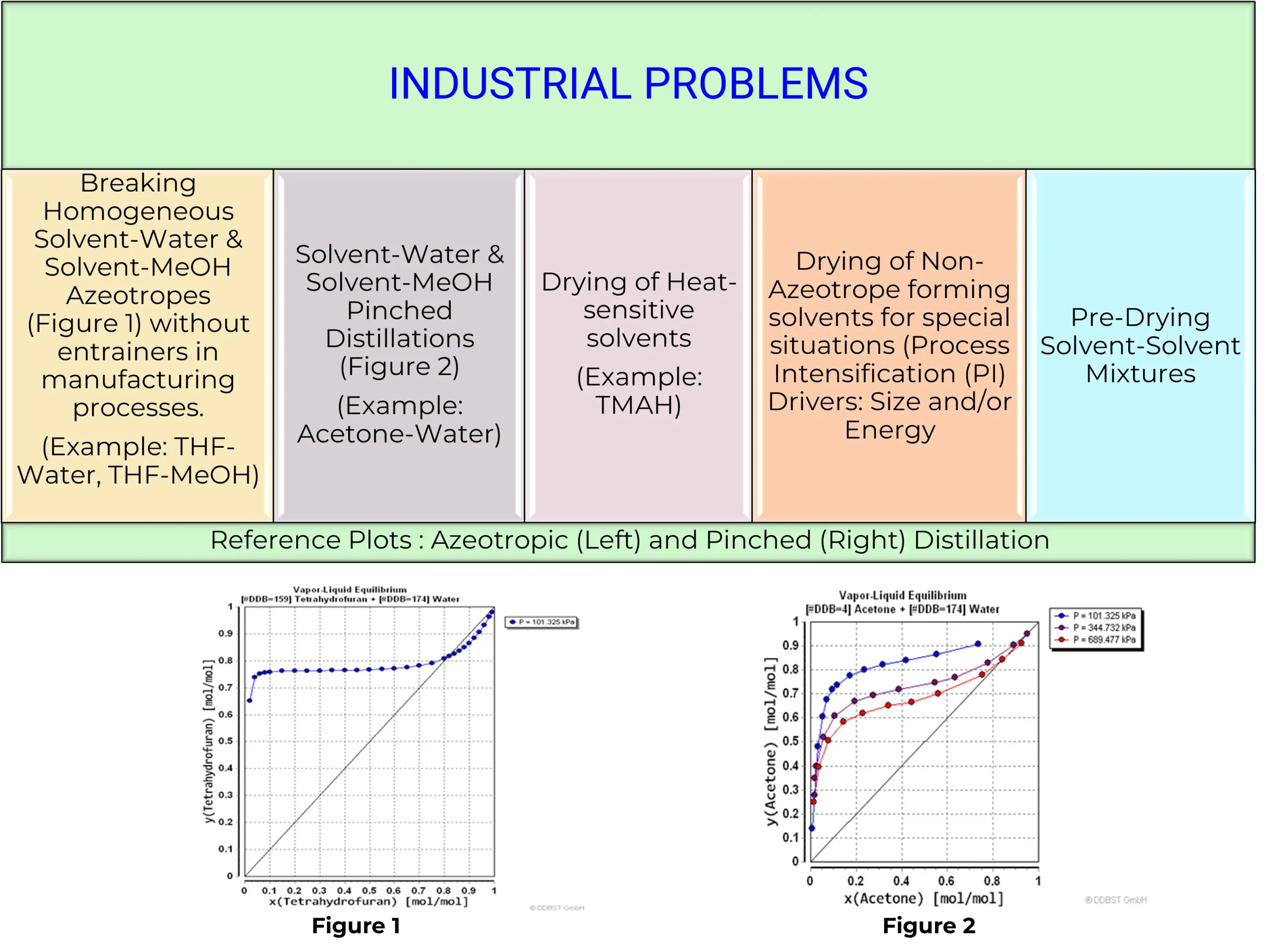

Some of the industrial separation problems that can be solved using Pervaporation are listed below.

Pervaporation & Vapor Permeation Applications

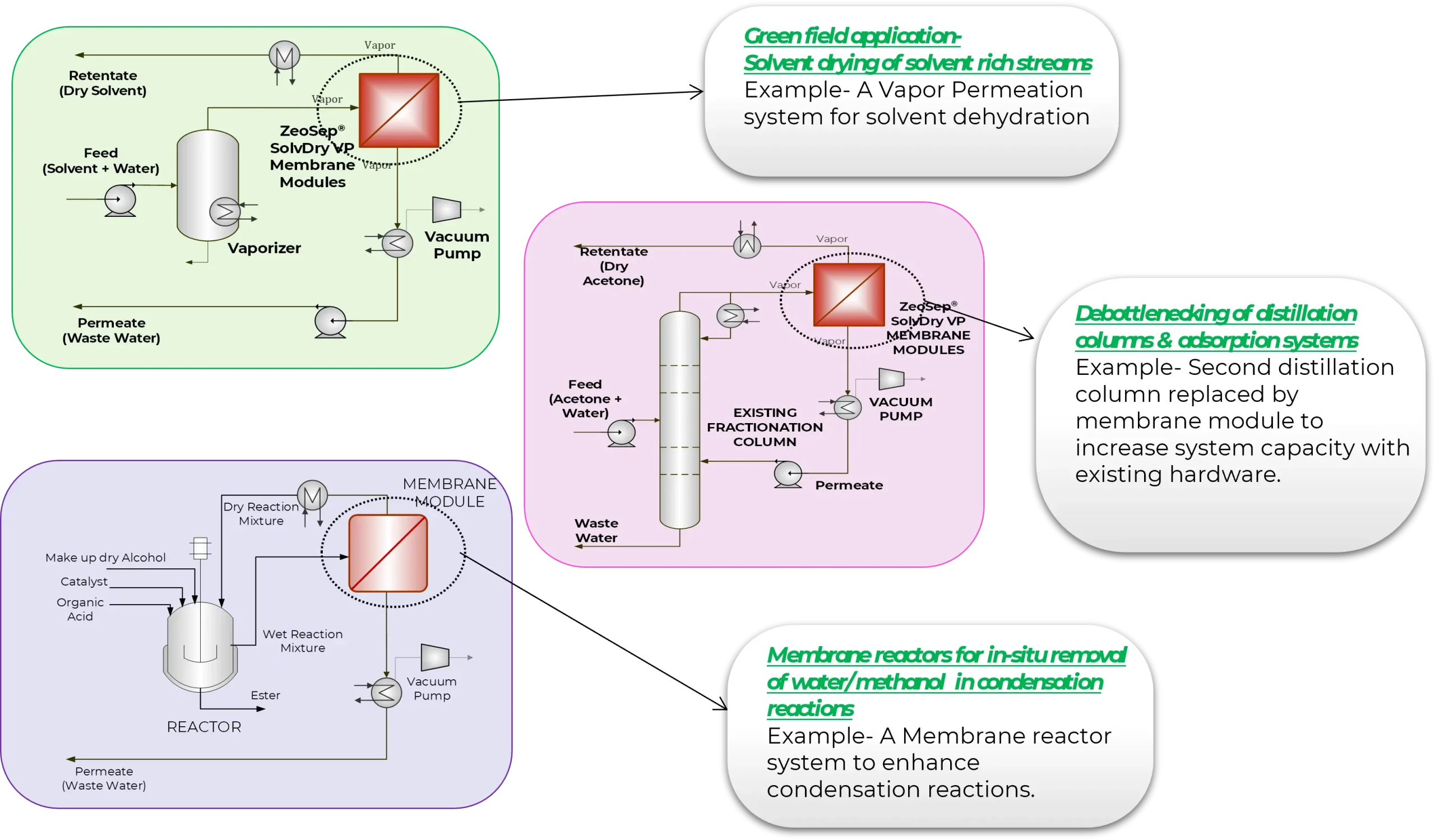

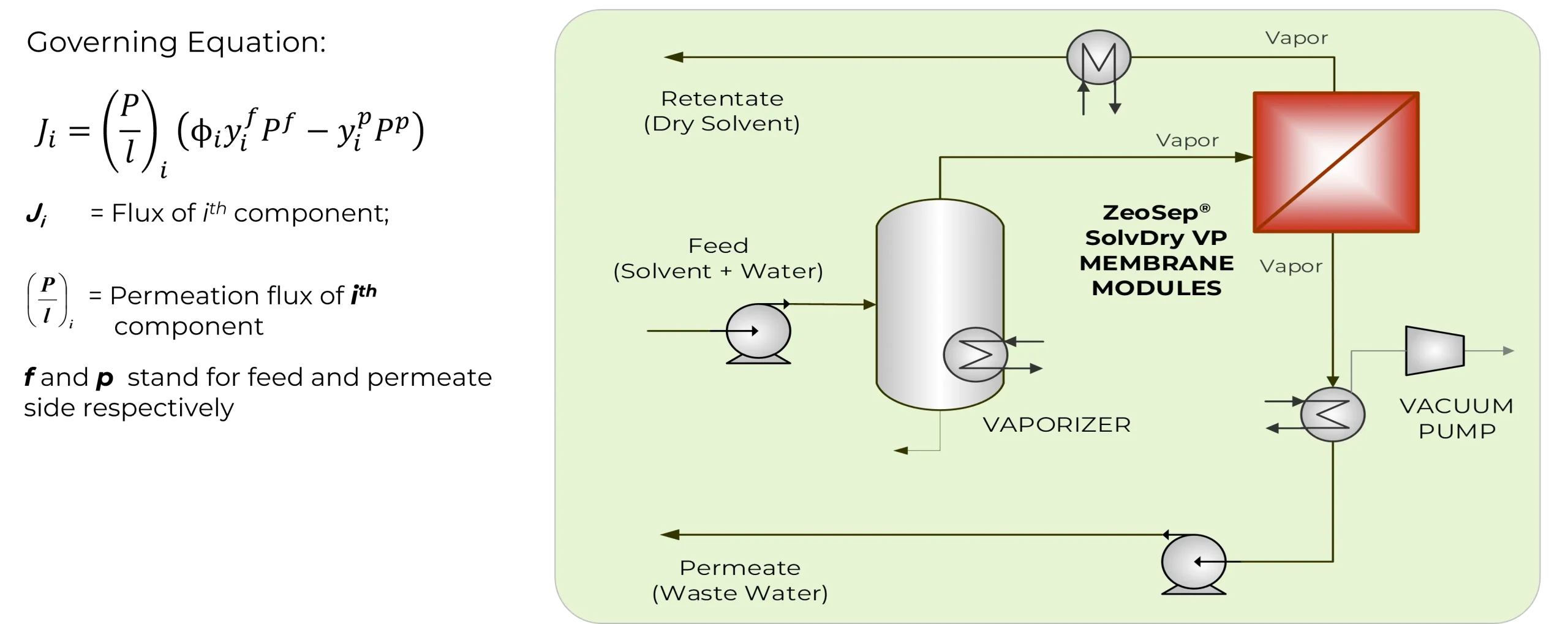

ZeoSep® Vapor Permeation (VP)

The schematic process flow diagram has been shown for ZeoSep® SolvDry Vapor Permeation (VP) Membrane System. The Solvent-Water mixture Feed is vaporized and sent to the Membrane Module to separate out water as the Permeate and Dry Solvent as the Retentate.

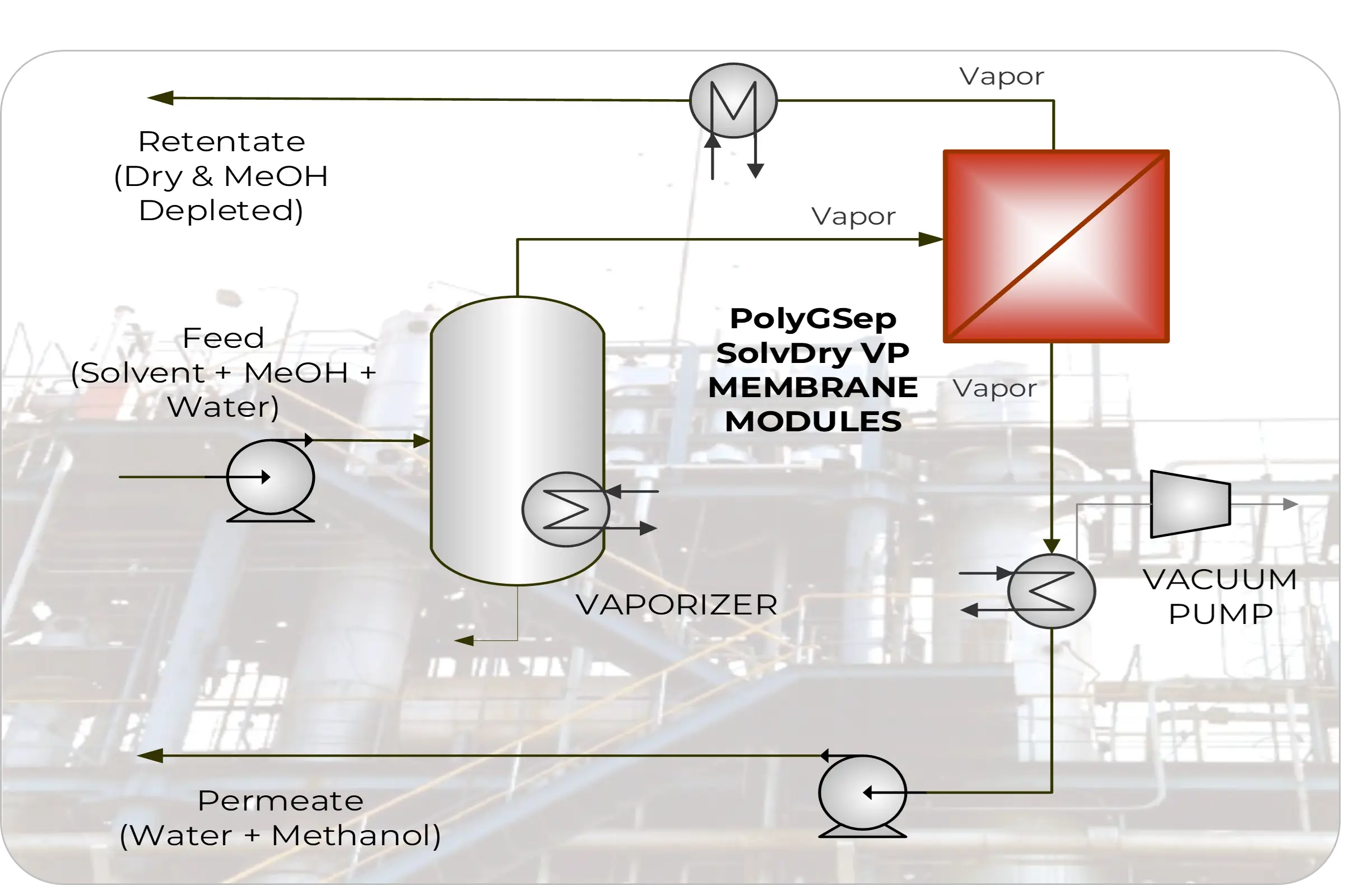

PolyGSep Vapor Permeation (VP)

The schematic process flow diagram has been shown for PolyGSep SolvDry Vapor Permeation (VP) Membrane System. The Solvent-Water mixture Feed is vaporized and sent to the Membrane Module to separate out water as the Permeate and Dry Solvent as the Retentate. In case Methanol is present in the mixture which has to be separated, it can be done using PolyGSep membranes to permeate Methanol out along with water.

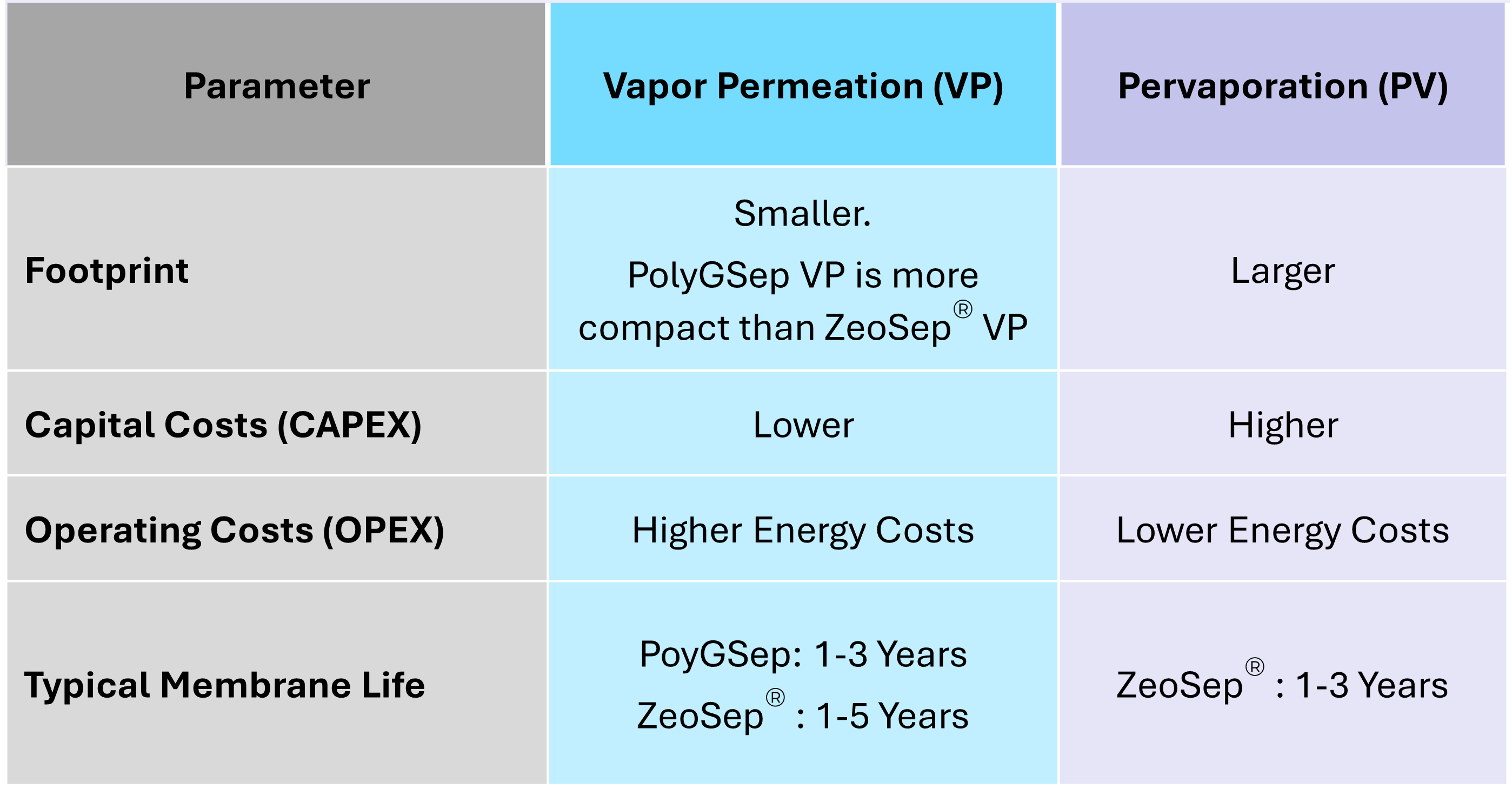

Vapor Permeation (VP) vs Pervaporation (PV)

The fitment of the mode of operation is checked on case-by-case basis. The high-level comparison (for high feed water content) is given in table below: