Our Vision and Mission are driven by our dedication to provide sustainable solutions to fulfil our commitment towards the society and environmental conservation and protection.

OUR VISION

Empower communities with practical process intensification solutions and promote scientific, innovative & entrepreneurial temperament.

OUR MISSION

- Be a world leader in the field of miniaturization and modularization chemical process plants using advance nanomaterials.

- Develop novel technologies by nurturing covalent bonds with academia & industry.

- Foster entrepreneurial skills, enable youngsters with functional knowledge, tools, methods and financing resources.

- Create a technology incubator to fuel the growth of material science enabled process intensification

Our Beliefs

“Never doubt that a small group of thoughtful, committed citizens

can change the world; indeed, it is the only thing that ever has.”

– Margaret Mead (1901 – 1978) quoted John M. Richardson, ed. Making it happen, 1982

“Nature is inexhaustibly sustainable if we care for it.

It is our universal responsibility to pass a healthy earth onto our future generations”

– Sylvia Dolson

Healthy People, Healthy Bottom-line

Meet the Team

Management

Manish Goel

Founder & CKO

Manish has 20 years of experience in development and commercialization of sustainable processes using process intensification. He is Masters in Chemical Engineering from Rensselaer Polytechnic Institute, Troy, New York. Manish, an Isermann Fellow, Department of Chemical Engineering, Rensselaer Polytechnic Institute, Troy, NY, 1993-1994 graduated in Chemical Engineering from University of Osmania, Hyderabad is university gold medalist and recipient of Prof Y Nayudamma Memorial Medal. He is the recipient of Certificate of Accomplishment by Department of Energy, US, under the “Dawnbreaker” Commercialization Assistance Program. He has two US Patents and several research publications to his credit. He has several international patents in process. Manish’s expertise includes developing and commercializing safe, environment friendly, energy-efficient and economical membrane based process technologies for sustainable manufacturing. Besides, Manish has also been offering courses on membrane based unit operations to scientists and engineers to equip them with knowledge and tools for comparison of membrane processes vis-à-vis conventional processes.

MKE Prasad

Formerly associated with Technip for 26 years out of 40 years in Process Industry and held position of Senior Vice President, Process & Technology, MKE Prasad is associated with us as an Advisor to our Leadership and R&D Team. An expert in Process Designing and Engineering, QHSE, Project Planning and Management possesses. He has Chemical Engineering degree from Osmania University. He also holds a diploma in Management Studies from Jamnalal Bajaj Institute of Management Studies.

Rohit Prasad

A Mechanical Engineer with 39 years of rich experience in refining industry in maintenance; start-ups, sales and project execution in public sector (Indian Oil) and technology sector (UOP). Out of this, he has 33 years of experience in project management related to Engineering, Procurement, Construction, Field Services etc. in refining area.

Rajiv Krishen

Has 40 years experience including 30 years association with Technip for and held the position of Senior Vice President. He is now an Advisor to our Leadership team. His expertise in Business Process Improvement, Organizational Development, Project Management & Cross functional Team Leadership is instrumental in designing and improvement of our business processes. He did Electrical Engineering from Punjab Engineering College, Chandigarh, in 1975.

Our USPs

We strive for exceeding our customer’s expectations.

Crafted on Pivotal Design Thinking and Double Diamond Approach, our products are designed for ease of operation for the End-user/Operator.

Our conviction that end user/operator can do no wrong – except malintent, gross negligence, is the underlying philosophy of our solutions.

We only undertake what we can deliver.

We provide comprehensive warranties and extraordinary guarantees.

Our functional and technical knowledge, our beliefs and values, human resources and infrastructure allow us to exceed our customer’s expectations and we improve continually upon our functional and technical knowledge, human resources and infrastructure.

Our Expertise

Rapid Concept to Commercialization offering quick payback

Clean & Green Molecular Separations

Process Intensification Know-how

Membrane Materials Know-how

Commercial Technologies

Why Clean & Green?

Safe & Non-hazardous, Mild operating conditions, Low leachables & extractables, Physical separation without the use of chemicals, No side reactions, Minimal effluents & emissions, Energy Efficient, High Recovery

What we do?

Fields of Application

- Breaking azeotropes (Solvent-H2O & Solvent-MeOH) without entrainers

- Pinched distillation separations

- Removal of water from reaction mixtures

- Drying of volatile heat-sensitive solvent mixture

- Separation of dissolved solids, water and volatile (or non volatile) organics

Engineered Goods and Services

- Modular Systems

- Membranes and Housings

- Peripheral Proprietary Equipment

- Leased Systems

- Custom Designed Processes & Process Licensing

- Plant Support Services

- Process Technology Development & Licensing?

- MembrainingTM –Membrane Training: Fundamentals to Practice

Value Proposition

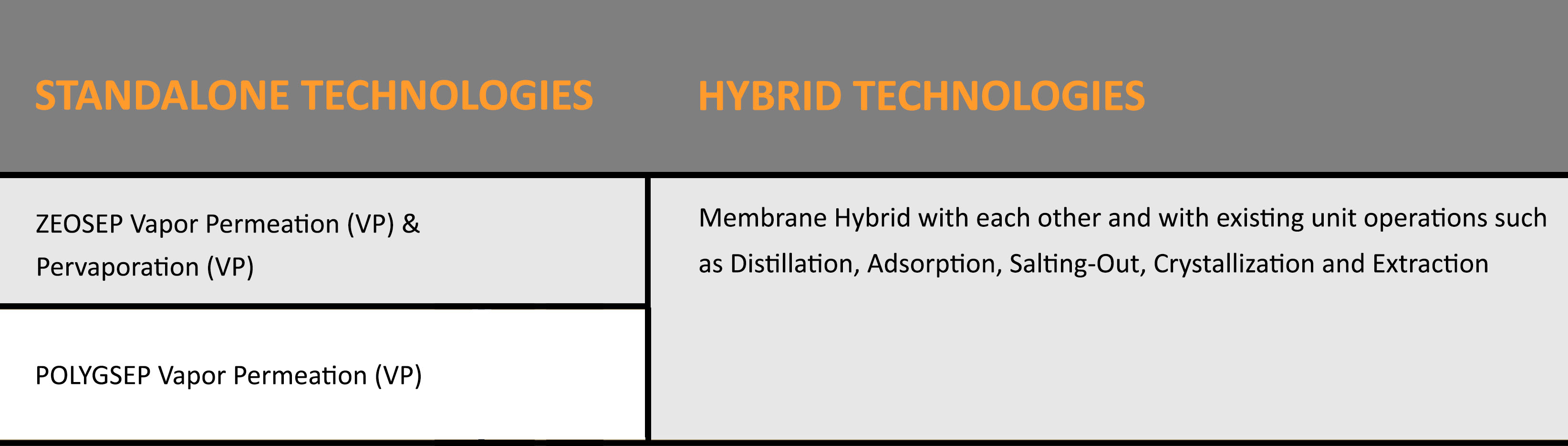

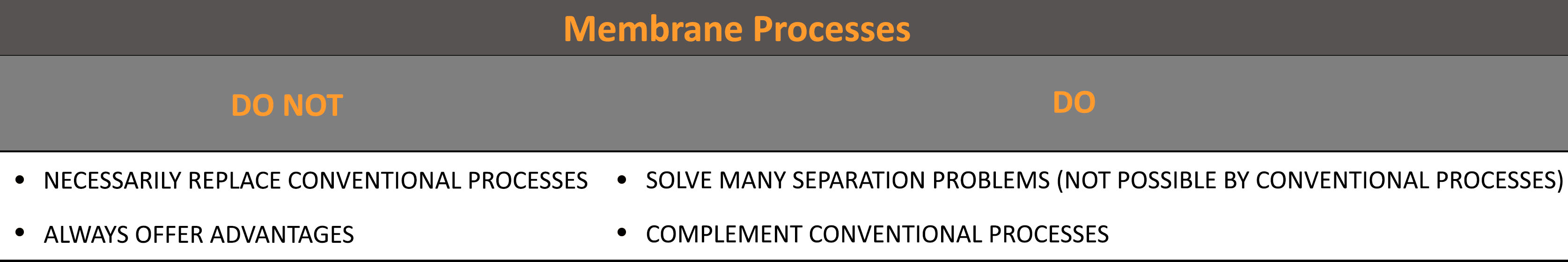

Membrane Processes are a valuable separation tool in a Green Process Engineers’ tool kit, used for a variety of industrial scale applications in API manufacturing and other industries.

Membranes can last for many years without cleaning & replacement using systematic and methodical Process Development, Transfer & Implementation